- Products & Services

- Energy Management and Sustainability

- Design Engineering Services

- Energy Audits and Assessments

- Cable Testing

- Electric Vehicle Infrastructure

- Lighting

- Who We Serve

- Company

- Customer Stories

- Incentives

- Contact Us

- FR

- Products & Services

- Energy Management and Sustainability

- Design Engineering Services

- Energy Audits and Assessments

- Cable Testing

- Electric Vehicle Infrastructure

- Lighting

- Who We Serve

- Company

- Customer Stories

- Incentives

- Contact Us

- FR

A class-act move to cut carbon.

A class-act move to cut carbon.

Affordably.

Background

In the changing world of energy management, a new trend is emerging among buildings deemed Class A as part of the Industrial Conservation Initiative (ICI).

The ICI program rewards heavy electricity users for shifting their usage to off-peak periods. By doing so, these Class A customers get a better global adjustment rate, helping them make serious cuts to their energy bills.

The City of Ottawa is taking note. Consider its Mary Pitt Centre, for example, a facility historically heated by three natural gas boilers. A building that, in theory, should be too expensive to heat electrically given its size and the price gap between natural gas and electricity.

With the building’s Class A status, however, the City’s taking smart steps to partially electrify the heating and cut even more utility costs in the process.

Background

In the changing world of energy management, a new trend is emerging among buildings deemed Class A as part of the Industrial Conservation Initiative (ICI).

The ICI program rewards heavy electricity users for shifting their usage to off-peak periods. By doing so, these Class A customers get a better global adjustment rate, helping them make serious cuts to their energy bills.

The City of Ottawa is taking note. Consider its Mary Pitt Centre, for example, a facility historically heated by three natural gas boilers. A building that, in theory, should be too expensive to heat electrically given its size and the price gap between natural gas and electricity.

With the building’s Class A status, however, the City’s taking smart steps to partially electrify the heating and cut even more utility costs in the process.

Approach

Envari installed an electric boiler in the mechanical room. Controlled by a price-dispatch signal, the boiler runs when the hourly electricity price falls below that of natural gas. It’s a sensible, incremental way to cut carbon and energy costs by periodically fuel-switching.

It was important, however, not to modify the physical infrastructure or control logic with the existing boiler plant; this is a critical City building, so the new boiler had to be supplemental to provide peace of mind to the operations staff and property manager.

The electric boiler was strategically placed upstream from the gas boilers and configured to provide hotter water.

As this hotter water runs through the hydronic loop and passes the gas boilers, they’re tricked into thinking the building doesn’t need heat. It keeps them from turning on when they shouldn’t be operating.

Approach

Envari installed an electric boiler in the mechanical room. Controlled by a price-dispatch signal, the boiler runs when the hourly electricity price falls below that of natural gas. It’s a sensible, incremental way to cut carbon and energy costs by periodically fuel-switching.

It was important, however, not to modify the physical infrastructure or control logic with the existing boiler plant; this is a critical City building, so the new boiler had to be supplemental to provide peace of mind to the operations staff and property manager.

The electric boiler was strategically placed upstream from the gas boilers and configured to provide hotter water.

As this hotter water runs through the hydronic loop and passes the gas boilers, they’re tricked into thinking the building doesn’t need heat. It keeps them from turning on when they shouldn’t be operating.

Results

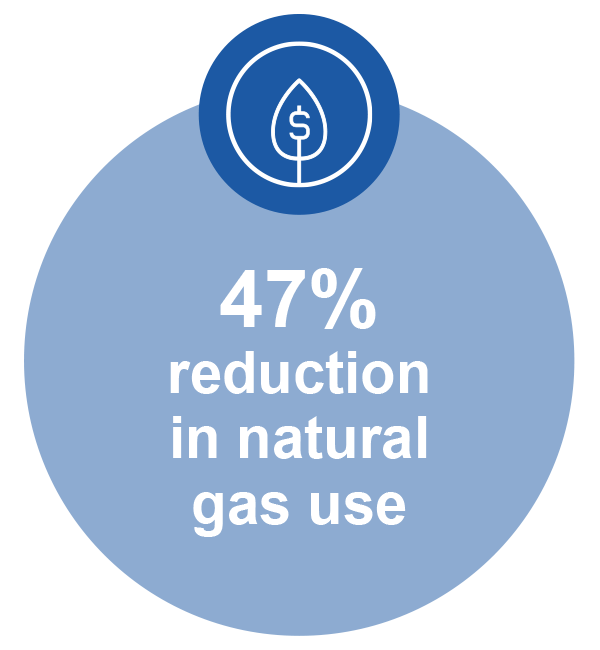

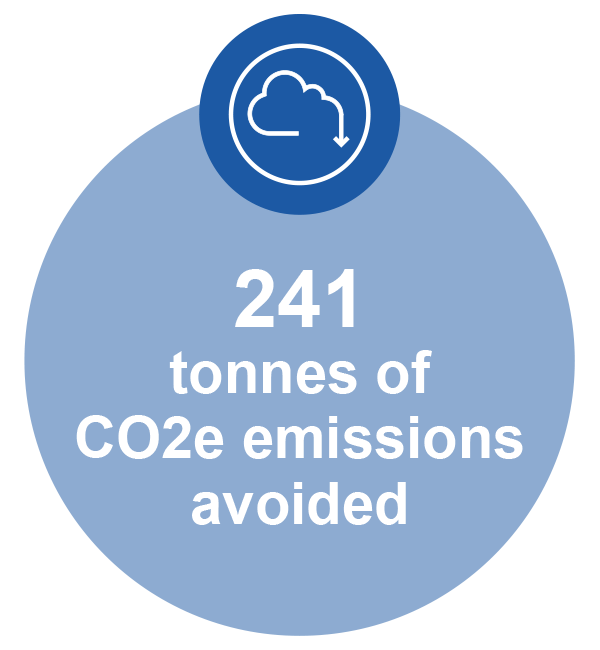

By using intelligent automation to occasionally heat electrically, the Mary Pitt Centre is taking steps to decarbonize while keeping its costs low.

Expected annual savings are $22,000 in electricity costs and 260 tonnes of CO2e, which is the equivalent to planting 12,227 new trees.

Also, the fuel-switching is helping extend the life of the natural gas boilers. A win-win all around.

Results

By using intelligent automation to occasionally heat electrically, the Mary Pitt Centre is taking steps to decarbonize while keeping its costs low.

Expected annual savings are $22,000 in electricity costs and 260 tonnes of CO2e, which is the equivalent to planting 12,227 new trees.

Also, the fuel-switching is helping extend the life of the natural gas boilers. A win-win all around.

Have questions about your building’s ventilation?

We’re here to help. Contact our energy experts today.

Contact us

Thank you for reading the story!

We received your message. One of our representatives will contact you to start a discussion or answer any questions you may have.

Browse similar stories: